At Vervida, we create regenerated yarn for a world moving toward conscious creation.

At Vervida, we create regenerated yarn for a world moving toward conscious creation.

For decades, Vervida has been the silent engine powering the world’s most trusted textile brands. We’re more than just a cotton yarn manufacturer; we are a strategic bulk supply partner, built on a foundation of scale, efficiency, and unwavering commitment.

Our journey began with a simple vision: to transform premium cotton into the most consistent and high-performing yarn on the market. Today, through continuous investment in state-of-the-art machinery and vertically integrated operations, we’ve achieved a production capacity few can match. This scale ensures supply chain resilience and the bulk volume necessary to fuel your largest production runs, delivering millions of kilograms of precision-spun yarn annually.

Move beyond commodity. Our R&D focuses on creating premium, performance-driven products like Compact Spun, Core Spun, and specialized blends. We deliver the innovative textile foundation needed for your next generation of fabrics.

Our expansive product line is engineered to serve the full spectrum of textile manufacturing needs, from high-volume basics to luxurious, fine-gauge apparel.

Ideal For: Denim, general-purpose woven fabrics, toweling, hosiery, and budget-friendly knitwear (T-shirts, casual wear).

Premium bedding, fine-gauge knits, high-end apparel, shirting fabrics, and garments requiring excellent print clarity.

Luxury apparel, high-speed automated weaving/knitting, specialized stretch fabrics, and products where low imperfection is critical.

Activewear (Core-Spun), fashion denim (Slub), unique color-effect knits (Mélange), and cost-optimized durable workwear (CVC/Poly-Cotton).

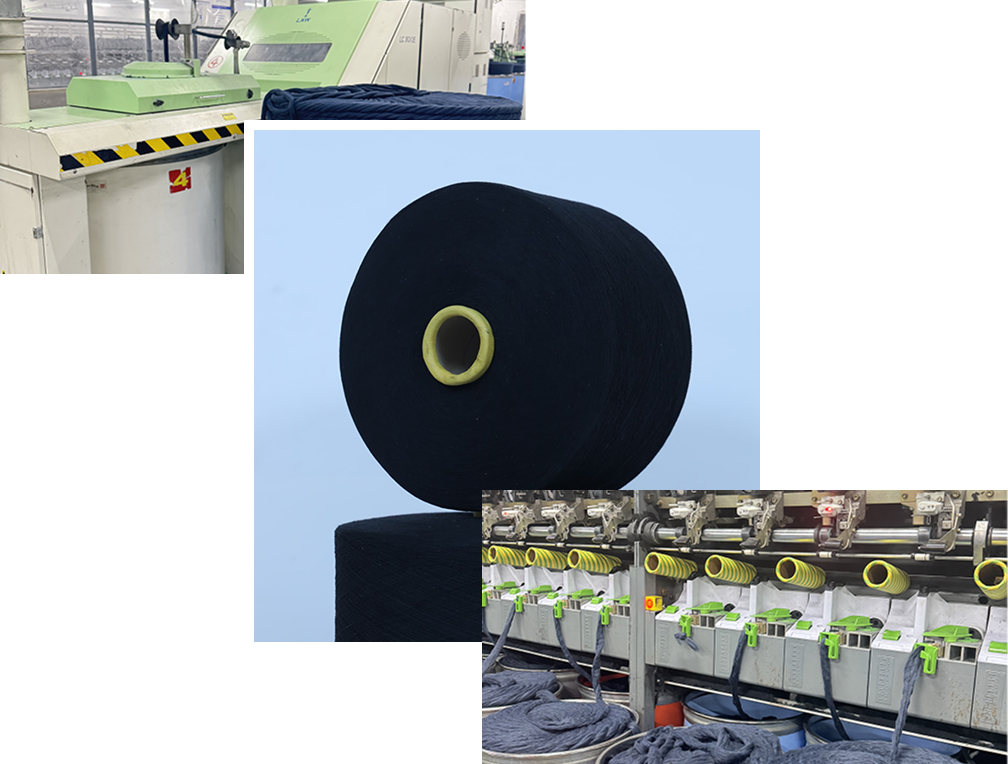

At Vervida, every strand of yarn tells a story of precision, innovation, and quality. Our manufacturing process is designed to transform raw cotton into world-class yarn through a series of meticulously controlled stages.

The Blowroom marks the first stage in yarn production, where raw cotton is opened, cleaned, and blended to remove impurities. This ensures uniform fiber mixing and a consistent base for further processing.

In the Carding process, cotton fibers are meticulously disentangled, cleaned, and aligned. This stage converts the fluffy mass into a fine, uniform sliver, eliminating short fibers and impurities.

Drawing combines multiple carded slivers to achieve uniform thickness and fiber alignment. This controlled stretching process ensures evenness and strength while enhancing fiber blending for consistency.

Open End Spinning is the final stage where prepared slivers are converted into yarn. Using modern rotor spinning technology, fibers are twisted and wound into stable, high-strength yarns.

Being part of Vervida has been a journey that’s both personal and professional. I’ve grown up understanding the care, precision, and passion that goes into every batch of our yarn. I still remember the first time I walked through the spinning floor and felt the soft cotton between my hands — it made me realize that quality isn’t just a standard here, it’s a promise. Today, that same attention to detail guides everything we do, ensuring that each yarn carries the dedication and heart of our team.

Quality Control Director | Vervida

Watch how Vervida brings sustainability and innovation together, turning ideas into impact.

Our open-end spinning process combines innovation, speed, and reliability. Using advanced rotor technology, we produce high-quality yarns with excellent strength and uniformity. The result — fewer machine stops, smoother production, and greater value for your supply chain.

We use mordern Rotor spinning to ensure fast and efficient yarn production. These machines help us maintain consistent quality while minimizing yarn breaks and waste.

Our cotton fibers are carefully opened, cleaned, and blended using advanced machinery to ensure evenness and purity. This preparation ensures smooth rotor spinning and strong, durable yarn.

Behind every machine stands a skilled team that keeps Vervida running with care and commitment. Our operators, technicians, and quality experts monitor every stage, from fiber prep to final yarn, ensuring accuracy that no automation can replicate.

Mr. Rakesh Bansal – Founder, Vervida

With over 20 years of experience in the textile industry, Mr. Rakesh Bansal has been the driving force behind Vervida’s growth and vision. His deep understanding of textile manufacturing, combined with a forward-thinking approach to sustainability, has shaped Vervida into a brand that stands for quality, innovation, and responsibility.

For our B2B partners, certainty is everything. Vervida’s operations and products are rigorously audited by leading international third parties, ensuring every fiber meets the highest global benchmarks for quality control, human safety, and environmental stewardship.